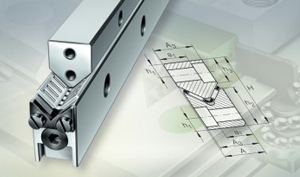

J/S Guideways With Needle Roller Flat Cage (INA) These guidance systems comprise J and S guideways separated by needle roller flat cages. They are used as non-locating bearings and for limited stroke lengths. The guideways are supplied in high and flat versions. The cages made from metal or plastic and are of single or double row design.

flat-cage-guidance-systems-ina

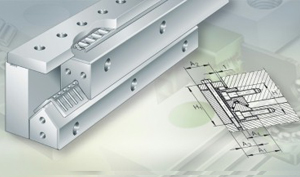

The basic design comprises the M/V guideway pair and angled flat cages containing needle rollers or cylindrical rollers and is a linear locating bearing. The guideways are supplied in grades Q2, Q6 and Q10. The cages are made from metal or plastic. Metal cages are suitable for more demanding conditions such as high acceleration, high temperatures and where the ends of the cage are exposed at some point in operation. Plastic cages are particularly economical for simple operating conditions. Accessories include end pieces for the guideways and wipers to protect the raceways against contamination.

the basic design comprises the ml/v guideway pair with an adjusting gib and angled needle roller flat cages. These guidance systems are preloaded using the gib; the gib applies the preload uniformly over the whole length of the guideway. The pitch of the gib surface is 1,5%. When the gib is moved by 1 mm, the height changes by 15 µm. The guideways are supplied in grades q6 and q10. the cages used are double row angled needle roller flat cages made from metal or plastic. m/v guideways with integral toothed rack and angled flat cage the basic design comprises the m/v guideway pair with an integral toothed rack and angled needle roller flat cages with an integral gear. This variant is used where there is a risk of cage creep, for example in designs with non-uniform rigidity in the guidance area or where the cage does not regularly move to the end positions. The guideways are supplied in grades q2, q6 and q10. the cages are made from metal, are of double row design and are subject to positive control by the integral gear.

Counterstay system with needle roller and cylindrical roller flat cages (INA) this counterstay system is a linear locating/non-locating bearing unit. Due to the subdivision into locating and non-locating bearing arrangements, the system is not distorted by thermal expansion. The locating bearing system comprises m/v guideways and the non-locating bearing system j/s guideways. Needle and cylindrical roller flat cages are arranged between the guideways. The guidance system is preloaded by an l-shaped counterstay. The guideways are supplied in grade q2. the counterstay system is used where guidance systems must have high accuracy with extremely high rigidity and load carrying capacity and the adjacent construction must not be distorted by preload forces or thermal expansion. It has the highest accuracy of any rolling element linear guidance system, is particularly low-friction and very easy to fit, requiring no adjustment work after mounting.